Designing A National Park With An Optimized Approach To Using New Materials In Order To Prevent Global Warming

Shiva Babazadeh Namini

Faculty of Architecture and Urbanism Engineering “M.Sc” of Urbanism – Urban Design Trend Islamic Azad University of Qazvin, Barajin branch, Qazvin, Iran.

Abstract

A variety of materials have long been used by humans. Among these, steel and concrete can be mentioned as the most widely used construction materials. In recent years, due to high construction costs and environmental considerations, various waste and recycled materials are used. Recycling construction waste into raw materials is a promising method for processing these materials with significant environmental and economic benefits, but unfortunately it is rarely used in the community. In this study, in order to increase the level of knowledge of people in this field and encourage them to use these materials, a national park has been designed in Iran and in the city of Tehran. For this purpose, first the latest recycled materials are described and then it is considered as a part of the park. It should be noted that the materials have been mentioned that can be used in different climates of this country.

key words : National park, optimization, recyclable materials, materials produced from recycling materials, global warming

Introduction

national park, an area set aside by a national government for the preservation of the natural environment. A national park may be set aside for purposes of public recreation and enjoyment or because of its historical or scientific interest. Most of the landscapes and their accompanying plants and animals in a national park are kept in their natural state [8]. The national parks in the United States and Canada tend to focus on the protection of both land and wildlife, those in the United Kingdom focus mainly on the land, and those in Africa primarily exist to conserve animals. Yosemite, Sequoia, and General Grant national parks were established in the United States in 1890, and during this time the idea of protecting outstanding scenic natural areas for their own sake grew into a concept of American (U.S.) national policy[9]. The national park system was expanded during the following decades, and the U.S. National Park Service (NPS) was created in 1916 to administer the parks. By the early 21st century the NPS administered more than 400 separate areas constituting about 85 million acres (34 million hectares). In addition to national parks, the system included national preserves, monuments, recreation areas, seashores, lakeshores, historic parks and sites, parkways, scenic trails, and battlefields [10]. Partly inspired by the American example, movements in favour of national parks sprang up in many other countries, beginning with Canada, which established its first three national parks in the mid-1880s. Nature reserves had been maintained in Europe for centuries to protect hunting grounds for use by kings and nobles, but the establishment of modern national parks and nature reserves gained momentum only after World War I or, in some cases, after World War II [11]. Great Britain established the administrative machinery for both national parks and nature reserves in 1949. It also began establishing national parks in India and its African colonies after the war, and this practice was continued and expanded by those new nations after reaching independence. Japan and Mexico established their first national parks in the 1930s, but interest in parks generally came later in Asia and Latin America than it did in the Anglo-American countries and Europe [12]. The growing importance of these areas is not only their protective aspect, but also its effects on humans. Protected areas are currently an important component of the landscape and should be evaluated periodically; Because they preserve natural values and provide great benefits to communities [13]. The main role of protected areas is nature protection. Protecting nature means preventing the destruction and destruction of ecosystems, species and various aspects of natural environmental values [14]. The situation of destruction of protected areas in comparison with the history of pasture and forest destruction is still wide and diverse and due to lack of attention and sufficient knowledge of people and officials and the large number of destruction factors such as exploration and exploitation projects, road construction projects Electricity, oil and gas transmission, urban and rural development, land use change, forestry projects and even reckless afforestation have become a recurring and unresolved issue [15]. Due to the importance and role of protected areas in various aspects of education, research, recreation and tourism, research studies in these areas are very necessary [16]. The increase in construction in cities is accompanied by the demolition of not-so-old buildings. Buildings, most of which are made of new non-native materials such as clay bricks, slabs, plaster, cement, steel and glass. After destruction, this type of material is turned into garbage and accumulates on the outskirts of cities, causing environmental degradation and consequently pollution of cities. In the future, fully industrial and chemical materials such as aluminum, plastics, bitumen and composite materials such as asbestos and Iranites (used in new constructions) will be added to this waste [17]. Excessive and incorrect consumption of new materials has caused irreparable environmental damage, and from now on, with the prevalence of industrial materials, these damages will be more and more harmful. The energy consumed to produce new materials is enormous. High levels of GHG emissions are the result of the activities of the construction industry; for example, cement and steel production alone are responsible for 10.12% of global Green House Gas (GHG) emissions [18]. High energy consumption in the construction sector and many environmental challenges make it vital to review the construction process in the country. Effective and vital decisions are usually made in the building design process. During design, decisions are made that affect the environment and nature for the rest of the building’s life and even years after its demolition. The choice of materials is one of the decisions of the architect in the design process, which if not done properly and with study, it will be difficult to compensate for the damage [19]. Unfortunately, similar estimates are not available for construction debris from the construction of non-residential and commercial centers and the physical demolition of centers, including concrete structures, steel bridges, road construction and site clearance [20]. Due to the high volume of construction waste production in residential and non-residential sectors on the one hand and on the other hand the high volume of concrete consumption as the most widely used construction product while the dimensions and number of construction projects, especially in developing countries It is expanding, obviously, to what extent the recycling process of this waste can be necessary in preserving existing resources, which are sometimes non-renewable, as well as protecting the environment from the entry of this volume of construction waste[21]. Today, a lot of energy is spent on the production of construction materials, and various factories and industrial centers are operating in the field of production of construction materials, and this in itself increases the amount of pollution and global warming [22]. On the other hand, if recyclable materials are used, the amount of mass production of materials will be significantly reduced, and the produced materials can be used in several stages to reduce the amount of pollution and global warming [23]. Therefore, in this study, according to its title and contents, the design of the national park with the approach of optimizing the use of recyclable materials and materials made from recycling other materials, in order to prevent global warming. The purpose of this research is to design a national park in which recyclable materials and materials made from recycled other materials are encouraged to use these materials and the effects of using these materials on global warming are shown.

In general, the objectives of the present study can be expressed in the following terms :

1- Designing a national park to increase the knowledge and method of using recyclable materials and recycled materials from other materials, which is done in line with other purposes.

2- Reducing energy consumption in the building by using these materials and finally reducing the level of global warming.

3- Investigating the use of these materials in different parts of Iran according to the climatic conditions of Iran.

4- Reducing global warming by reducing material production and material recycling.

5- Utilizing recyclable materials native to Iran.

6- Review of the latest materials made from recycled other materials that can be used in Iran.

Theoretical

The materials that are left after the use of construction materials and the demolition of buildings are actually known as construction waste. Recycled materials in buildings are actually present in new buildings or those projects that have been demolished on site. The most common materials that remain on site after construction as recycled materials include concrete, wood, asphalt, coatings, metal and cardboard. These materials typically make up 70 to 95 percent of the discarded material in a residential or commercial location [24]. This is exactly the construction waste. Recycled construction materials are often thrown away; But in fact, they are valuable goods that can be recycled as new products or new methods can be used. When these materials are considered as waste, waste disposal should usually be considered as part of the cost of doing so. Therefore, managing the recycling and reuse of these materials as management options is an issue that engineers overlook in many construction projects. Recycling can be beneficial to the environment [25]. Recycling construction materials and demolition materials produced at a construction site is very important. The environmental benefits of recycling can be significant. Current reports show that if the concrete and asphalt produced in the waste are recycled each year, this would save millions of gallons of gasoline. Much of the energy savings come from reducing natural resource consumption, such as mining ore or extracting and refining oil. In addition to saving energy, recycling construction debris keeps mixing materials away from landfills [26]. In addition to environmental benefits, recycling unusable building materials can have economic benefits. Recycling or using materials on site for construction projects reduces the cost of transporting and disposing of materials.

Recyclable building materials

The construction industry is responsible for 75% of the land’s natural resource consumption. Rock, sand, iron and many other limited resources are mined in large quantities to meet market needs. In addition, construction projects themselves generate a lot of waste and waste. Construction waste can make up between 50 and 70 percent of all municipal solid waste. These wastes are usually emptied into landfills instead of being properly recycled, and this affects urban health systems and creates informal disposal sites. However, if more care is taken. These wastes can have a huge potential for reuse. Properly covered, it will withstand a great deal of adverse conditions. Recycling is the process of reusing discarded materials to return them to the production cycle. This process reduces the consumption of raw materials, reduces the total volume of waste and can create jobs for thousands of people. To start the process, an efficient separation and collection system is essential. Although the classifications are different in each country, there are generally two main classes. The first includes concrete, ceramics, stone and mortar, which make up the majority of construction waste. The latter includes wood, metal, glass, plastic, plaster and more. Below are the most common materials for recycling and their use [27].

Steel

Steel can be made from a combination of iron ore and coal, which is heated in a large furnace, or by recycling waste, which is made in an electric furnace. Steel recycling dates back to Roman times, when soldiers collected weapons left in trenches to produce new weapons. In fact, steel can be transformed into new objects without any loss of quality. When recycling, electricity consumption is reduced by 80%, and this can reduce environmental impacts and completely eliminate the extraction of raw materials [28] .

Concrete

Recycling concrete reduces construction waste and costs less. In the practice of recycling hardened concrete, a special crusher is used to produce what is known as recycled material. Until recently, recycled concrete was used only as a floor. However, the results show that structural elements up to 30 to 40 MPa can be created from these recycled materials using appropriate technologies. More importantly, recycled materials are about 10 to 15% lighter than perfect concrete aggregates, which weigh less per cubic meter, resulting in lower transportation costs and overall costs [29].

Wood

The use of modified wood is very popular. Properly covered, it will withstand a great deal of adverse conditions. They can be used in large structural parts, or as a shear to produce other synthetic products such as boxes, pallets, or as a support for various purposes. But even softer and cheaper wood can be recycled [30].

Plaster

Gypsum recycling is possible in construction, but if not disposed of properly, it can emit usable and highly toxic hydrogen sulfide. And cause contamination of soil and groundwater. However, if processed properly, recycled gypsum retains the same physical and mechanical properties of ordinary gypsum at a relatively lower cost [31] .

Expanded polystyrene (EPS)

Expanded polystyrene or EPS can also be recycled. EPS can be turned into raw materials for new plastic products when crushed and compressed. It can also be used for finishing or even painting [32] .

Glass

Although glassware is completely recyclable, the task of recycling window glass is a bit complicated. Due to its different chemical composition and melting temperature, it cannot be recycled alongside other glass objects. However, window glass can melt and turn into fiberglass again. Broken glass can be combined with concrete to create granite floors and tables [33] .

Zinc, aluminum, and fabric may also be reuse and recycling options. There are also items such as asbestos (latex), latex paints, chemical solvents, adhesives and lead paints that must be treated carefully to reduce their impact on the environment. Due to growing environmental concerns, attention to the entire life cycle of a substance has become crucial. In addition to reducing the possibility of dumping waste in hidden places and helping to reduce the pressure on landfills, recycling can lead to lower costs for both the environment and the consumer. In addition, it reduces the need to extract new natural resources and the costs of production and transportation [34].

Building materials produced from waste recycling

Wooden newspapers

This design and idea originated in Norway, where more than one million tons of paper and cardboard are generated each year as waste. This large volume can be recycled to the board. By the method of rolling paper and glue to create a dissimilar material in the system of known materials and materials, with the property of rigidity and hardness that makes it a usable board. In this process, sealed wood is obtained with waterproof and fire resistant properties, and used to make anything that is normally made of wood [35].

Application of recycled plastic in the production of new wood

One of the current problems of communities is the accumulation of plastic waste, which is very high in daily and domestic consumption, and its durability and lack of rapid and easy degradability, is mentioned as one of the problems of waste. But the solution of recycling it and combining it with wood can open an effective way. Of course, this compound has been used for several years, but less attention has been paid to the recycling method. The use of plastics in construction has a very wide range: such as sewer water pipes – anti-moisture layers – flooring – insulation, decoration on surfaces such as: walls, false ceilings, etc [36]. The combination of wood and plastic, It has the properties of both main constituents. The hardness and strength of these materials is between the hardness of wood and plastic, but its density will generally be higher than both. These materials are resistant to fungal and insect attacks and can be produced in complex shapes. It is worth mentioning that this material has a very beautiful appearance and has different structures, dimensions and shapes that can be offered in the market. Plastic wood composites produce very little waste [37]. Even the produced waste can be reused, and it is interesting that wood waste and agricultural waste and even plastic waste in waste can be used as raw materials in the production of this material. Plastic products are not biodegradable and when they are dispersed in the environment, they will cause many problems for the environment, so the recycling of these materials is very important from an environmental and economic point of view. The most appropriate way to increase is the material return cycle. Due to the significant volume of plastic waste and waste lignocellulosic materials (wood), recovery and reuse of these materials will be necessary. Fortunately, one of the important advantages of plastic wood composites is that plastic waste and recycled natural fibers can be used in their production [38]. Which can be a rich and cheap source in the production of materials that are produced without the use of raw materials, using these wastes and increasing demand for them, these materials achieve a kind of material value that is a motivating factor in This material will be used to make flooring and wall coverings for interior and exterior parts of the building and soundproof coatings, as well as plastic wood can be used to make urban and home furniture, cabinets and interior parts of the building. According to studies, children’s playground equipment and door and window frames of buildings can also be made of plastic wood to produce plastic wood composites, taking into account the different purity and application of the product [39]. Different methods are used b Using the hot press method, large-sized boards can be produced, and also the possibility of using large volumes of fibers that are biodegradable increases their compatibility with the environment. Boards made in this way are a serious competitor to MDF boards. One of the most important disadvantages of wood products is the emission of formaldehyde gas, which will be eliminated by using plastic wood boards. In addition, lignocellulosic wastes can be used in the manufacture of plastic wood boards, such as fine particles from sanding that can not be used in the manufacture of MDF boards [40]. Due to the properties of plastic wood composites and considering that organic and natural fillers can make up to about 95% by weight of the composite, so with the introduction of fibers and natural fillers into the plastic industry, plastic wood composites that A combination of wood fibers or other lignocellulosic materials is produced as a filler or reinforcement. These materials have many applications and can easily replace wood and plastic products in most cases. Construction, interior and exterior design Buildings and automobiles are the most important fields of application of these materials. However, the use of this material in construction and production of construction materials accounts for about 15% of the total production of this material, and it is interesting that so far none of the construction materials have reached such a market demand.

Cover for the roof using diapers

The use of all plastic waste in various forms is one of the materials that has been considered and researched. All those who have healthy disposable diapers and hygiene products in the trash can, even if they are not completely pure and somewhat impure, can be included in this recycling, as recycling plants separate the polymers from the waste. Organics use these polymers as substructures. Lack of moisture absorption and high resistance are the prominent features of these light and durable blocks.

Recy blocks

Spinning block is the name of a product made from recycled plastic bags. These colorful bricks are made from old plastic bags that do not decompose easily in nature and are difficult to recycle in any other product. Recycled bags or plastic packaging are placed in thermal molds and in compression conditions, to become blocks. They are very light in weight and can be used both as load-bearing walls and as a partition wall. This product is very good and suitable for dividing rooms or spaces.[41]

Brick Bottle

Using bottles instead of bricks This recycling proposal may be a little different, more so in that the bottles are turned into waste depending on consumption, and this proposal depends on the amount of consumption. In material recycling, waste can be used directly without any special process in changing its shape, size or even color. One of these wastes is unused bottles after consumption. Many companies now produce bottles in rectangular shapes or shapes that are easier to transport. The idea of using bottles for construction was conceived in 1965 by the Hanken Company [42]. Came up with the idea of using unused bottles instead of bricks. Who needed housing. Hanken believed that both cases could be resolved, provided that people agreed to build their homes with bottles after

consuming them. Realizing his vision to volunteer for military service called a Dutch architect. John . It was Habraken who came up with the design for the glass brick walls, and Henken himself was the seller, or N. John Habraken, the maker of the glass bricks. While Hanken struggled in his first costly and difficult endeavor to produce and sell his product that pursued his goals, he was finally able to come up with the right design for it[43]. A piece of emerald green to realize the achievement of the work for the buyer of a drink and WOBO. His design as a builder was considered a suitable building material. In 1863, the first test to produce 100,000 bottles designed to recycle bricks came true. The bottles were designed in such a way that the neck of a bottle was attached to the next base, while both sides of the bottle were coated with mortar. For better connection, corners and openings and even surfaces on the glass were designed as small protrusions for better connection of mortar, and bottles were produced in two sizes, 500 mm and 350 mm. The way the bottles are placed is such that the top of the bottle opening is in a straight line at the bottom of the bottom of the bottle. The WOBO design did not have a special shape because each bottle with a thickness of natural glass in its length was able to withstand a weight of 50 kg horizontally. In addition, the square shape in the glass body made it easy to transport and even build. Maybe the only limitation was how the glasses were connected because no two glasses were perfectly joined at the end [44].

Fungal walls

To insulate the walls as well as to pack the materials, the researchers found a fungus that is caused by bacteria in a variety of agricultural products that cause parts of plants to rot, such as tree trunks and various agricultural products. The production method is as follows: If this produced bacterium is placed in a mold and the growth conditions of these organic materials are provided, it will grow in two days according to the shape of the mold. It can then be stopped from growing by a stove. This product is very useful and is used for traditional insulation and packaging of materials that tend to be unstable, so that the materials lose their tendency to decompose. For example: This method is a good alternative to the use of asbestos It is toxic.[45]

Plasphalt

Plasphalt is the name of a product that consists of plastic grains produced from disordered plastic waste. These materials replace sand in the traditional way in the production of asphalt. In the experiment, it was found that roads made of “asphalt” are far less likely to be vulnerable to wear and tear than traditional asphalt, because plastic emulsions are grafted from sand or gravel and produced better than asphalt. They work in the traditional way and are more durable [46].

Cork panels (production of cork panels(

According to available statistics, about 31.7 billion bottles are produced per year with cork caps, which can be easily separated from the bottles and returned to the production cycle. The walls or floors can be covered with cork plates (or panels). Use is suitable for walls and floors of spaces. The production process of this type of panels is done using a kind of binder (special adhesives) and mold at the required temperature. The lightness of the product, and the properties of sound, moisture and heat insulation are the prominent features of this new product [47].

Research background

To date, various researches have been done in the Recyclable and recycled materials from other materials, some of which are described below. The purpose of [1] analyses literature reviews on low-carbon material, starting from international policies on GHG emission reduction and CE principles, providing a critical summary of current knowledge. On the basis of a thorough literature review whose references have been made in accordance with the relevance of the topic of study, the approaches adopted in order to produce low-carbon materials, the materials investigated and the related issues and challenges, the work identifies in an original way eight approaches (known as Low-carbon Emission Approaches – LEAs) related to the production process that could help reduce the GHG emissions of construction materials. Comparing the results of the literature review analysis with the material life cycle by means of a matrix that relates LCA and LEAs, the paper underlines LEA’s capability to reduce GHG levels. In particular, focusing on the 8 LEAs identified, it emerges that, in order to create low-carbon products for construction, it is possible to use alternative materials (up to .40% of GHG emission) and natural materials (up to .90%), to introduce secondary raw materials (up to .40/50%), to implement CCS and CCU systems in the production process (up to .70%), to increase the use of energy from renewable sources (up to .60%), and to increase product performance. The purpose of [2] presents a comprehensive overview of literature reporting on the reuse of CRT glass to prepare glass-ceramics; cement mortar, paste, and concrete; and bricks. The effects of various critical factors on the resulting productsf performance, preparation mechanisms, leaching behavior, lead fate, and environmental and human safety were investigated. The comparison of these recycling methods, and directions for future research were discussed and reported as well. Preparing cement mortar, paste, and concrete from CRT glass offer added advantages in terms of quantity of recyclable cathode ray tube glass at a given time, with minimal environmental and economic implications and thus could be an a promising value-added uses for CRT glass. The geographical distance between waste CRT glass sources and processing facilities, public policies should be taken into account in its recycling. In study [3], the current and most recent literatures considering plastic recycling method and the influence of plastic materials on the fresh and mechanical properties of SCC are summarized. So that a comprehensive review can be provided in which the reviewed studies are categorized into sub groups based on whether they dealt with SCC containing plastic aggregates (PAs) or plastic fibers (PFs). Furthermore, the effect of RP on the fresh and mechanical properties of various self-compacting composites like self-compacting mortar (SCM), self-compacting high strength concrete (SCHSC) and self-compacting light weight concrete (SCLC) have been reviewed to illustrate the differences with normal SCC. The empirical relationships among various mechanical properties were also developed. Based on the obtained results from previous studies, recycled plastic self-compacting concrete (RPSCC) can be used for structural applications due to its satisfactory fresh and mechanical properties. Moreover, this type of concrete is environmentally friendly and sustainable product due to replacing the natural aggregates (NA) with plastic materials. The aim of the study [4] is to provide a sustainable benchmark optimization framework that can be well used to evaluate the sustainability of green materials in concrete production. A case study using fly ash geopolymer concrete in Melbourne showed that a 3.63% to 41.57% and 23.80% to 30.25% reduction could be achieved for greenhouse gas emissions and production costs, respectively, if an optimized framework is implemented. . The results of the scenario indicate 3 to 8% GHG and an increase in cost if materials are not available locally. A similar approach can be used to optimize the environment and save on other cement substitutes. Further studies on the comparison of environmental savings and costs of other cement substitutes using the developed framework are encouraged. This framework will be valuable for designers in deciding on sustainable cement alternatives.

In paper[5], literature dealing with use of waste recycled glass as partial replacement of either cement or aggregate in concrete is systematically reviewed. The focus of this review is the influence of recycled waste glass on the engineering properties of concrete. Main advantages and drawbacks of using recycled waste glass are discussed. The aim of this review is to identify major research needs in the field that will help bring this class of materials closer to worldwide practical use. Given that concrete is the most used man-made material in the world, such development would significantly reduce the need for landfilling of waste recycled glass that is unsuitable for reuse in glass production.

Research method

The method of the present study is library and descriptive. Initially, basic information was collected through library studies. Then, based on the climatic conditions of Iran, the recycled materials presented to date are considered as part of the park and how to use them is described. It should be noted that the present research has been done in order to design a national park in Iran. For this purpose, data has been collected for this country.

Area of study

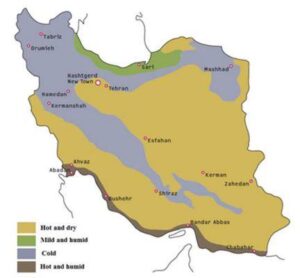

Iran has a hot, dry climate characterized by long, hot, dry summers and short, cool winters. The climate is influenced by Iran’s location between the subtropical aridity of the Arabian desert areas and the subtropical humidity of the eastern Mediterranean area. January is the coldest month, with temperatures from 5‹C to 10‹C, and August is the hottest month at 20‹C to 30‹C or mor . Iran can be divided in at least four different climate zones. The Climate of the Western and southwestern areas can be classified as BWh Climate; a hot, dry desert climate with annual average temperatures above 18‹C. a small zone between the Persian Gulf the turkisch Border in the mid of Iran can be classified as BSh climate, a hot, dry Climate with the annual average Teperature above 18‹C. The eastern and northern areas of Iran have a Csa Climate; a mild, semi-humid climate with dry summers, mild winters and the warmest month above 22‹C. Finally, the mountainous regions of northern Iran can be classified as Dsa Climate, a cold snow Climate with dry summers and wet winters with the warmest month over 22‹C and the coldest month below -3‹C(Fig 1).

Fig 1: area of study

National Park Design

1.Park location

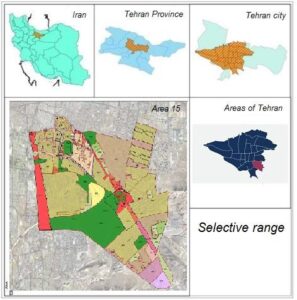

In this research, the location of the park in Tehran is from Tehran province in Iran. Also, the location of the park in the 15th district of this city has been considered in more detail. The reason for choosing this area is the existence of a wide range of worn texture. Of course, there has been significant activity in the field of immunization of these tissues, but it has not been enough. Logic 15 of Tehran Municipality is located in the southeast of the city and with an area of about 500, 16 hectares, has accommodated about 800 thousand people of Tehran. It is bordered by District 21 to the south, District 14 to the north, and Regions 12 and 16 to the northwest and west, respectively [7] (Fig 2).

Fig 2: area of study

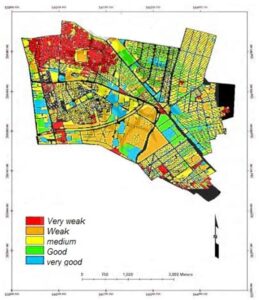

In this paper, a combination of FAHP and TOPSIS methods, a new method for selecting the optimal location using GIS is used. In this regard, the criteria for selecting the optimal location to create urban green space were entered and compared in the FAHP model and then the output of the FAHP model was used as the weight of the criteria in the TOPSIS model. Classification of spatial spaces in the 15th metropolitan area of Tehran for the construction or zoning of green spaces using the combined technique of FAHP and TOPSIS models was done very well, well, moderately, poorly and very poorly [7] (Fig 3).

Fig 3 : Map of the optimal location of Mel Park in District 1 of Tehran Municipality using the combined model of FAHP and TOPSIS[7]

2.Different parts of the park

2.1. Building and structural materials

This section describes recyclable or recycled structural materials that have been invented to date. In the park, a structure is made and exhibited from each of these materials. It is also explained about the suitability of these materials in their use in different climates of Iran.

2.1.1. Animal blood next building material

Munrofs gBlood Bricksh are created by first mixing fresh blood with an anticoagulant (EDTA) to prevent it thickening too quickly. Although he used bullocks, blood from other animals could also be used. He then adds sodium azide as a preservative to prevent decomposition and bacteria growth. After a number of unsuccessful attempts at creating a glue by adding chemicals such as glacial acetic acid, Munro turned to the simpler combination of blood and water that is then mixed with sand .Placing the resulting mixture in formwork and baking it for an hour at 70‹ C (158‹ F) for an hour causes the blood proteins to coagulate to produce a stable, waterproof brick. With Munro estimating that 30 liters (7.9 gal US) of blood could be recovered from a single bullock and sand plentiful, he believes Blood Bricks have the potential to replace mud bricks as a building material in arid regions (Fig 4) .

Fig 4: animal blood

2.1.2. Recycled Buildings Made from Bottles, Cans

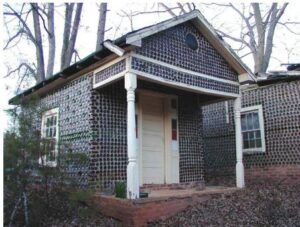

Bottle walls sounds like something a quirky eccentric would construct just for fun. In point of fact, the oldest surviving bottle house was constructed out of over 50,000 beer bottles in 1907, due to the lack of lumber available in the deeserts of Nevada. Though many bottle buildings are decades old, recent structures around the world have been built out of necessity in places where both building supplies are scarce and other recycling methods are unavailable [48]. (Fig 5)

Fig 5: Recycled Buildings Made from Bottles

2.1.3. Straw bale houses

Straw bale houses also make use of a common and regularly sized material that is relatively available and inexpensive. This regularity makes working with the building blocks relatively easy. Many such houses, once they are completed and covered outside and in, do not even look to be made of straw [49]. (Fig 6)

Fig 6: Straw bale houses

2.1.4. Cardboard house

A cardboard house may seem even more implausible than one constructed of beer cans. With the right water-proofing, however, just such a house would be not only sustainable but also exceedingly affordable. This so-called house of the future is designed with exterior waterproofing and water storage under the floor to protect it from the water and from blowing over in the wind. Of course, cardboard is also a highly collapsible building material, making the shipment of the house also more environmentally friendly, efficient and inexpensive (Fig 7).[50]

Fig 7: cardboard house

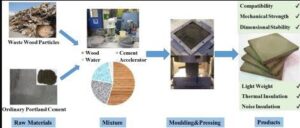

2.1.5. Particleboard glued with sound and heat insulation cement

These materials are suggested in the article [6], which states that Large amounts of waste wood formwork from construction sites end up with landfill disposal every day. This study aims to develop a practicable technology for recycling construction waste wood into formaldehyde-free cement-bonded particleboards that have value-added features of high strength, light weight, and thermal/noise insulation for reuse in building and construction applications. The mineralogy and microstructure of particleboards were characterized by X-ray diffraction, thermogravimetry, and mercury intrusion porosimetry analyses. Among the mineral admixtures, chloride accelerated precipitation of oxychlorides while sulphate produced calcium sulphoaluminate for promoting early strength development. The use of 2% CaCl2 proved to be sufficient for improving the wood-cement compatibility. At wood-to-cement ratio of 3:7 by weight (3:1 by volume), cement hydrates in the porous structure ensured acceptable dimensional stability (<2% swelling). By adjusting the water-to-cement ratio to 0.3 and density of the particleboards to 1.54 g cm.3, the volume of capillary pores was effectively reduced from 0.16 mL g.1 to 0.02 mL g.1. The more compact microstructure contributed to high fracture energy at 6.57 N mm.1 and flexural strength of 12.9 MPa. Using the above optimal production conditions, the particleboards complied with the International Standard (9 MPa) while enabling reuse as light-weight structure. The particleboards also manifested outstanding structure-borne noise reduction (at 32.100 Hz) and low thermal conductivity (0.29 W m.1 K.1), suggesting potential application as acoustic and thermal insulating materials. Preliminary cost-benefit analysis illustrated economic viability of the proposed approach. Therefore, technological innovation is crucial for delivering an eco-friendly solution to waste wood recycling for the building and construction industry (Fig 8).

Fig 8: Particleboard glued with sound and heat insulation cement

2.1.6. Transforming Food Waste Into Building Materials

The report notes that in the United Kingdom, 60 percent of raw materials are used for construction, while more than 40 million tons of dried organic waste was produced in European agriculture and forestry industries in 2014. There could be a big potential to transform that dried organic waste into something useful for such a big industry; and it could be quite profitable, as the report also points out that a kilogram of waste incinerated for energy recovery might only bring in .0.85 (USD $0.98), while the same kilogram of material converted into interior cladding might bring in .6 (USD $6.95), meaning there’s both economic and environmental benefits to this approach.The idea is to take advantage of the increasing amount of organic waste that is coming from growing cities, which could be reused and re-incorporated back into the building industry, or shifting from a linear consumption model into a “circular economy” where the supply chain is a closed loop that reuses so-called waste: Organic waste is not restricted to the countryside but it extends more significantly to the urban environment. Cities aggregate a large amount of resources. This includes both a high concentration of biological nutrients coming from rural areas as food – that rarely return to the agricultural system thus causing damage where they are discharged – as well as resources directly produced at urban level – as the biological waste coming from parks, trees, urban agricultural systems, community gardens, green roofs and facades. So it’s a big deal that Arup is advocating such a “circular” approach to our waste streams: after all, as a company with over 14,000 staff, 90 offices and projects in 160 countries, Arup’s reach and size means that if such bio-materials gained more ground with both the private and public sectors, we could soon be building with food waste, literally. As Arupfs European materials consulting lead Guglielmo Carra explains: As one of the worldfs largest users of resources we need to move away from our etake, use, disposef mentality. There are already pockets of activity, with some producers making lower carbon building products from organic materials. What we need now is for the industry to come together to scale up this activity so that it enters the mainstream. An important first step is to work with government to rethink construction codes and regulations to consider waste as a resource, opening up the opportunity to repurpose it on an industrial-scale (Fig 9) .

Fig 9: Transforming Food Waste Into Building Materials

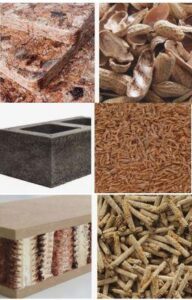

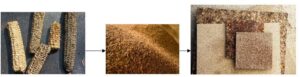

2.1.7. building materials from recycled agricultural waste (Fig 10).

Fig 10: building materials from recycled agricultural waste

2.1.8. Building blocks using plastic waste

The first thing you will probably notice about large building blocks is how beautiful they look. Each has a vibrant color combination because the resulting plastic waste, such as water bottles, packaging and other disposable items, is still visible. Each brick is made by heating, compressing and combining recycled materials. That’s why ByBlock introduces itself as the latest alternative to landfill. With Fusion with material recycling facilities, waste management operations, it works with municipalities and organizational partners to increase the receipt of more waste as its raw materials, and in this process, 30 tons of waste is used per month. It should be noted that the use of ByBlocks in construction

activities will not reduce the quality. Unlike concrete, these bricks do not crack or break. In addition, with the possibility of making this brick or block in the form of puzzle pieces, the need to use materials or glue is greatly reduced [51](Fig 11).

Fig 11: Building blocks using plastic waste

2.2. National Park Hiking Trails

This part of the park is designed from materials obtained from the recycling of materials and other materials. Which are discussed below.

2.2.1. Filter Pave Driveways

Higbee, Missouri-based FilterPave claims its product is twice as porous as asphalt, four times as porous as conventional pavers, it helps filter pollutants from stormwater and also prevents erosion. The material, made with tumbled pebbles of post-consumer recycled glass, is laid on a deep bed of gravel. The lifespan of the pavement is about the same as asphalt. A special topcoat prevents UV rays from breaking down the glue. The cost is $8 to $12 per square foot. Homeowners are encouraged to contact the company to find a recommended installer in their area [52](Fig 12).

Fig 12: Filter Pave Driveways

2.3. Interior decoration

In this part of the park, recycled materials will be unveiled that can be used in the field of interior decor.

2.3.1. combining cork on the outside and crumbs

In these buildings, by combining cork on the outside and crumbs on the inside, they create a thick thermal and sound insulation. These materials do not require maintenance, are durable and fully recyclable, and prevent any thermal bridges (Fig 13).

Fig13: combining cork on the outside and crumbs

2.3.2. Use of recycled plastics and glass in interior decoration (Fig 14).

Fig14: Use of recycled plastics and glass in interior decoration

2.3.3. Use of non-mineral stones in interior decoration (Fig 15).

Fig15: Use of non-mineral stones in interior decoration

2.3.4. Ultra Touch insulation

UltraTouch insulation is made in Chandler, Arizona with 80 percent post-consumer recycled denim and recycled carpet fibers. The manufacturer, Bonded Logic Inc., also coordinates the Blue Jeans Go Green program where retailers such as J. Crew, Madewell and American Eagle Outfitters collect old jeans to be made into the insulation, which is then donated to school and library construction projects and Habitat for Humanity. Therefs no reason household cast-offs should be destined for the dump.plenty of nearby agencies are more than willing to give your old stuff a second life. UltraTouch, which has an R value of 6.7, is $37 for a six-roll case at The Home Depot [53](Fig 16).

Fig16: UltraTouch insulation

2.3.5. Milliken Carpet Tiles with Econyl

In the six years since its introduction, Econyl has been embraced by dozens of large and small carpet companies including Ege, Desso, Interface, Avondale Carpets and Tarkett. The innovative nylon yarn is produced in Slovenia from post-consumer waste materials such as fishing nets and textiles. Aquafil, the company behind Econyl, uses a chemical process that gun-zipsh nylon 6 molecules from landfill fodder and returns the molecules to their monomer state. The resulting organic compound, caprolactam, can then be turned into new nylon 6 polymers which are identical to the ones made from crude oil. The process can be repeated an infinite number of times with no loss in quality. South

Carolina-based carpet company Milliken is one purveyor that has embraced Econyl. It offers eight collections made from the yarn.Clerkenwell is shown here (Fig 17) .

Fig 17: Milliken Carpet Tiles with Econyl

2.3.6. Ceilume Tiles

Ceilumefs thermoformed ceiling tiles are made of 100-percent recycled plastic manufacturing scrap. The Sonoma County, California-based company also recycles all of its own production waste and takes back scrap from customers, creating a closed-loop lifecycle (Fig 18).

Fig 18: Ceilume Tiles

Conclusion

Iran is one of the developing countries in which a lot of energy is spent annually on production in the field of construction. This, in turn, has increased the level of pollution in this country. Also, the increasing number of construction and non-construction waste has affected the country’s metropolises. Due to this issue, the use of new materials that are produced from the recycling of materials or other materials, helps a lot in this area. Therefore, in this study, recyclable materials were first investigated. According to the results, most of the materials used in construction today are recyclable, but these materials have three main problems. First, the production of these materials is expensive and produces a lot of pollution. Second, there is less inclination in society to recycle and reuse these materials. Third, little research has been done on the direct use of these materials in recycled form. Due to the production waste worldwide, more research has been done on recycling non-construction waste and using them as construction materials. Therefore, in this research, a national park in Iran was designed in line with the research. For this purpose, first the different climates of Iran were discussed. Then, the latest materials that can be used in these climates were described, and finally the national park was designed based on them. According to the obtained results, it can be said that the implementation of this park can increase the level of knowledge and use of these materials in construction, which will reduce pollution and reduce greenhouse gases. According to the materials mentioned and the climates of Iran can use all these materials in all climates of Iran. However, it is suggested that the materials expressed in terms of heat and sound be studied and their exact applications be interpreted .

Reference

1- Orsini, F., & Marrone, P. (2019). Approaches for a low-carbon production of building materials: A review. Journal of Cleaner Production, 241, 118380 .

2- Yao, Z., Ling, T. C., Sarker, P. K., Su, W., Liu, J., Wu, W., & Tang, J. (2018). Recycling difficult-to-treat e-waste cathode-ray-tube glass as construction and building materials: A critical review. Renewable and Sustainable Energy Reviews, 81, 595-604.

3- Faraj, R. H., Ali, H. F. H., Sherwani, A. F. H., Hassan, B. R., & Karim, H. (2020). Use of recycled plastic in self-compacting concrete: A comprehensive review on fresh and mechanical properties. Journal of Building Engineering, 30, 101283.

4- Sandanayake, M., Gunasekara, C., Law, D., Zhang, G., Setunge, S., & Wanijuru, D. (2020). Sustainable criterion selection framework for green building materials.An optimisation based study of fly-ash Geopolymer concrete. Sustainable Materials and Technologies, 25, e00178 .

5- Paul, S. C., .avija, B., & Babafemi, A. J. (2018). A comprehensive review on mechanical and durability properties of cement-based materials containing waste recycled glass. Journal of Cleaner Production, 198, 891-906.

6- Wang, L., Chen, S. S., Tsang, D. C., Poon, C. S., & Shih, K. (2016). Value-added recycling of construction waste wood into noise and thermal insulating cement-bonded particleboards. Construction and Building materials, 125, 316-325 .

7- Poorahmad, A., Shadmani Rudposhti, M., Hasanpour, S., Shahrabi Farahani, A., Faraji Rad, K. (2015). Site Selection for Green Space in Region 15 of Tehran City by Geographic Information System (GIS). Human Geography Research, 47(1), 33-46.

8- Ramkissoon, H., Mavondo, F., & Uysal, M. (2018). Social involvement and park citizenship as moderators for quality-of-life in a national park. Journal of Sustainable Tourism, 26(3), 341-361.

9- Gigovi., L., Pourghasemi, H. R., Drobnjak, S., & Bai, S. (2019). Testing a new ensemble model based on SVM and random forest in forest fire susceptibility assessment and its mapping in Serbiafs Tara National Park. Forests, 10(5), 408.

10- Carvache-Franco, M., Segarra-Ona, M., & Carrascosa-Lopez, C. (2019). Segmentation and motivations in eco-tourism: The case of a coastal national park. Ocean & Coastal Management, 178, 104812.

11- Swanson, F. H. (2020). Wonders of Sand and Stone: A History of Utah’s National Parks and Monuments. University of Utah Press.

12- Netshakhuma, N. S. (2019). Assessment appraisal, disposal and transfer of neglected rangersf diaries created from 1926 to 1930: case of the Kruger National Parks of South Africa. Collection and Curation.

Nat. Volatiles & Essent. Oils, 2 022; 9(1): 1270-1293

1291

13- Leal, C. (2019). National Parks in Colombia. In Oxford Research Encyclopedia of Latin American History.

14- Kim, J., Thapa, B., Jang, S., & Yang, E. (2018). Seasonal spatial activity patterns of visitors with a mobile exercise application at Seoraksan National Park, South Korea. Sustainability, 10(7), 2263.

15- Young, T. R. Most important, despite the global focus on climate change, national progress on many of the substantive components of climate change (pollution of land, water and air; destruction of protected areas, forests and untouched ecosystems/landscapes; etc.) seems to be rolling back, whether by direct actions and threats of more such roll-backs (as in the US), by lack of enforcement, or by the determination that national standards should be altered to reflect the (lower) standards described under international ….

16- Gowlland, G. (2020). The materials of indigeneity: slate and cement in a Taiwanese indigenous (Paiwan) mountain settlement. Journal of the Royal Anthropological Institute, 26(1), 126-145 .

17- Duan, H., Miller, T. R., Liu, G., & Tam, V. W. (2019). Construction debris becomes growing concern of growing cities. Waste Management, 83, 1-5.

18- Ram, V. G., Kishore, K. C., & Kalidindi, S. N. (2020). Environmental benefits of construction and demolition debris recycling: Evidence from an Indian case study using life cycle assessment. Journal of Cleaner Production, 255, 120258.

19- Bhatia, R., & Kumar, A. (2019). Model tests on geosynthetic-encased construction concrete debris column in fly ash fill. Innovative Infrastructure Solutions, 4(1), 1-14.

20- Mistri, A., Bhattacharyya, S. K., Dhami, N., Mukherjee, A., & Barai, S. V. (2020). A review on different treatment methods for enhancing the properties of recycled aggregates for sustainable construction materials. Construction and Building Materials, 233, 117894.

21- Heisel, F., Schlesier, K., & Hebel, D. E. (2019, August). Prototypology for a circular building industry: the potential of re-used and recycled building materials. In IOP Conference Series: Earth and Environmental Science (Vol. 323, No. 1, p. 012023). IOP Publishing.

22- Gomez, M., Peisino, L. E., Kreiker, J., Gaggino, R., Cappelletti, A. L., Martin, S. E., … & Raggiotti, B. B. (2020). Stabilization of hazardous compounds from WEEE plastic: Development of a novel core-shell recycled plastic aggregate for use in building materials. Construction and Building Materials, 230, 116977.

23- Paul, S. C., .avija, B., & Babafemi, A. J. (2018). A comprehensive review on mechanical and durability properties of cement-based materials containing waste recycled glass. Journal of Cleaner Production, 198, 891-906.

24- Balador, Z. (2020). Increasing the use of reclaimed and recycled building materials in New Zealand: Stakeholder perceptions.

25- Kong, M., Ji, C., Hong, T., & Kang, H. (2021). Impact of the use of recycled materials on the energy conservation and energy transition of buildings using life cycle assessment: A case study in South Korea. Renewable and Sustainable Energy Reviews, 111891.

26- Kong, M., Ji, C., Hong, T., & Kang, H. (2021). Impact of the use of recycled materials on the energy conservation and energy transition of buildings using life cycle assessment: A case study in South Korea. Renewable and Sustainable Energy Reviews, 111891.

27- Huang, B., Gao, X., Xu, X., Song, J., Geng, Y., Sarkis, J., … & Nakatani, J. (2020). A life cycle thinking framework to mitigate the environmental impact of building materials. One Earth, 3(5), 564-573.

Nat. Volatiles & Essent. Oils, 2 022; 9(1): 1270-1293

1292

28- Omer, M. A., & Noguchi, T. (2020). A conceptual framework for understanding the contribution of building materials in the achievement of Sustainable Development Goals (SDGs). Sustainable Cities and Society, 52, 101869.

29- Soomro, F. A., Memon, B. A., Oad, M., Buller, A. H., & Tunio, Z. A. (2019). Shrinkage of concrete panels made with recyclable concrete aggregates. Engineering, Technology & Applied Science Research, 9(2), 4027-4029.

30- Wang, Z., Hu, M., Wang, Q., & Li, L. (2022). Efficient and sustainable photocatalytic degradation of dye in wastewater with porous and recyclable wood foam@ V2O5 photocatalysts. Journal of Cleaner Production, 332, 130054.

31- Cordon, H. C. F., Cagnoni, F. C., & Ferreira, F. F. (2019). Comparison of physical and mechanical properties of civil construction plaster and recycled waste gypsum from Sao Paulo, Brazil. Journal of Building Engineering, 22, 504-512.

32- Marten, B., & Hicks, A. (2018). Expanded polystyrene life cycle analysis literature review: an analysis for different disposal scenarios. Sustainability: The Journal of Record, 11(1), 29-35.

33- Chen, T., Kazerooni, D., Ju, L., Okonski, D. A., & Baird, D. G. (2020). Development of recyclable and high-performance in situ hybrid tlcp/glass fiber composites. Journal of Composites Science, 4(3), 125.

34- Trowell, K. A., Goroshin, S., Frost, D. L., & Bergthorson, J. M. (2020). Aluminum and its role as a recyclable, sustainable carrier of renewable energy. Applied Energy, 275, 115112.

35- I.dinsky, J., Vidholdova, Z., & Reinprecht, L. (2020). Particleboards from recycled wood. Forests, 11(11), 1166.

36- Basalp, D., Tihminlioglu, F., Sofuoglu, S. C., Inal, F., & Sofuoglu, A. (2020). Utilization of municipal plastic and wood waste in industrial manufacturing of wood plastic composites. Waste and Biomass Valorization, 11(10), 5419-5430.

37- Lopez, Y. M., Paes, J. B., Gustave, D., Goncalves, F. G., Mendez, F. C., & Nantet, A. C. T. (2020). Production of wood-plastic composites using cedrela odorata sawdust waste and recycled thermoplastics mixture from post-consumer products-A sustainable approach for cleaner production in Cuba. Journal of Cleaner Production, 244, 118723.

38- Hasan, K. F., Horvath, P. G., & Alpar, T. (2022). Nanotechnology for waste wood recycling. In Nanotechnology in Paper and Wood Engineering (pp. 61-80). Elsevier.

39- Lopez, Y. M., Paes, J. B., Gustave, D., Goncalves, F. G., Mendez, F. C., & Nantet, A. C. T. (2020). Production of wood-plastic composites using cedrela odorata sawdust waste and recycled thermoplastics mixture from post-consumer products-A sustainable approach for cleaner production in Cuba. Journal of Cleaner Production, 244, 118723.

40- Basalp, D., Tihminlioglu, F., Sofuoglu, S. C., Inal, F., & Sofuoglu, A. (2020). Utilization of municipal plastic and wood waste in industrial manufacturing of wood plastic composites. Waste and Biomass Valorization, 11(10), 5419-5430.

41- Chaikaew, C., Sukontasukkul, P., Chaisakulkiet, U., Sata, V., & Chindaprasirt, P. (2019). Properties of concrete pedestrian blocks containing crumb rubber from recycle waste tyres reinforced with steel fibres. Case Studies in Construction Materials, 11, e00304.

42- Haque, M. (2019). Sustainable use of plastic brick from waste PET plastic bottle as building block in Rohingya refugee camp: a review. Environmental Science and Pollution Research, 26(36), 36163-36183.

43- Saikat, S. A., Khan, M. G. G., & Morshed, H. G. (2019). Investigation of Mechanical Properties of Plastic Bottle Brick.

Nat. Volatiles & Essent. Oils, 2 022; 9(1): 1270-1293

1293

44- Narayan Bansal, D., & Jain, R. (2020). COMPARISION OF MUD BRICK, SAND MUD BRICK AND PLASTIC SAND MUD BRICK.

45- Vigneshwar, P. V., Anuradha, B., Guna, K., & Kumar, R. A. (2021). Sustainable eco-friendly fly ash brick using soil filled plastic bottles. Materials Today: Proceedings.

46- Choudhary, A., Sarkar, A., & Safina Dhiman, J. J. (2020, January). m potentIAl of unICIpAl wAste As sustAInABle rurAl roAd ConstruCtIon mAterIAls In IndIA. In Proceedings of First National Conference on Sustainability in Built Environment (p. 184). BlueRose Publishers.

47- Antunes, A., Gomes, A., Paiva, N., Ferra, J., Martins, J., Carvalho, L., … & Magalhaes, F. D. (2018). Blocked melamine.urea.formaldehyde resins and their usage in agglomerated cork panels. Journal of Applied Polymer Science, 135(35), 46663.

48- Intini, F., & Kuhtz, S. (2011). Recycling in buildings: an LCA case study of a thermal insulation panel made of polyester fiber, recycled from post-consumer PET bottles. The international journal of life cycle assessment, 16(4), 306-315.

49- Li, H., Luo, Z., Xu, X., Cang, Y., & Yang, L. (2021). Assessing the embodied carbon reduction potential of straw bale rural houses by hybrid life cycle assessment: A four-case study. Journal of Cleaner Production, 303, 127002.

50- Diarte, J., Shaffer, M., & Obonyo, E. (2019). Developing a Panelized Building System for Low-Cost Housing Using Waste Cardboard and Re-purposed Wood. In Proceedings of the 18th International Conference on Non-Conventional Materials and Technologies (NOCMAT).

51- Nduko, J. M., & Taguchi, S. (2021). Microbial production of biodegradable lactate-based polymers and oligomeric building blocks from renewable and waste resources. Frontiers in Bioengineering and Biotechnology, 8, 1548.